Acrylic is a thin, transparent plastic material made of polymers of methyl methacrylate.

This sounds fancy, but it’s basically just a reactive resin.

It has great optical clarity and impact strength, while also maintaining flexibility.

Acrylic bonds well with adhesives and solvents. It also has amazing weathering properties when compared to other transparent plastics. Acrylic is super lightweight which can be nice for handling larger projects.

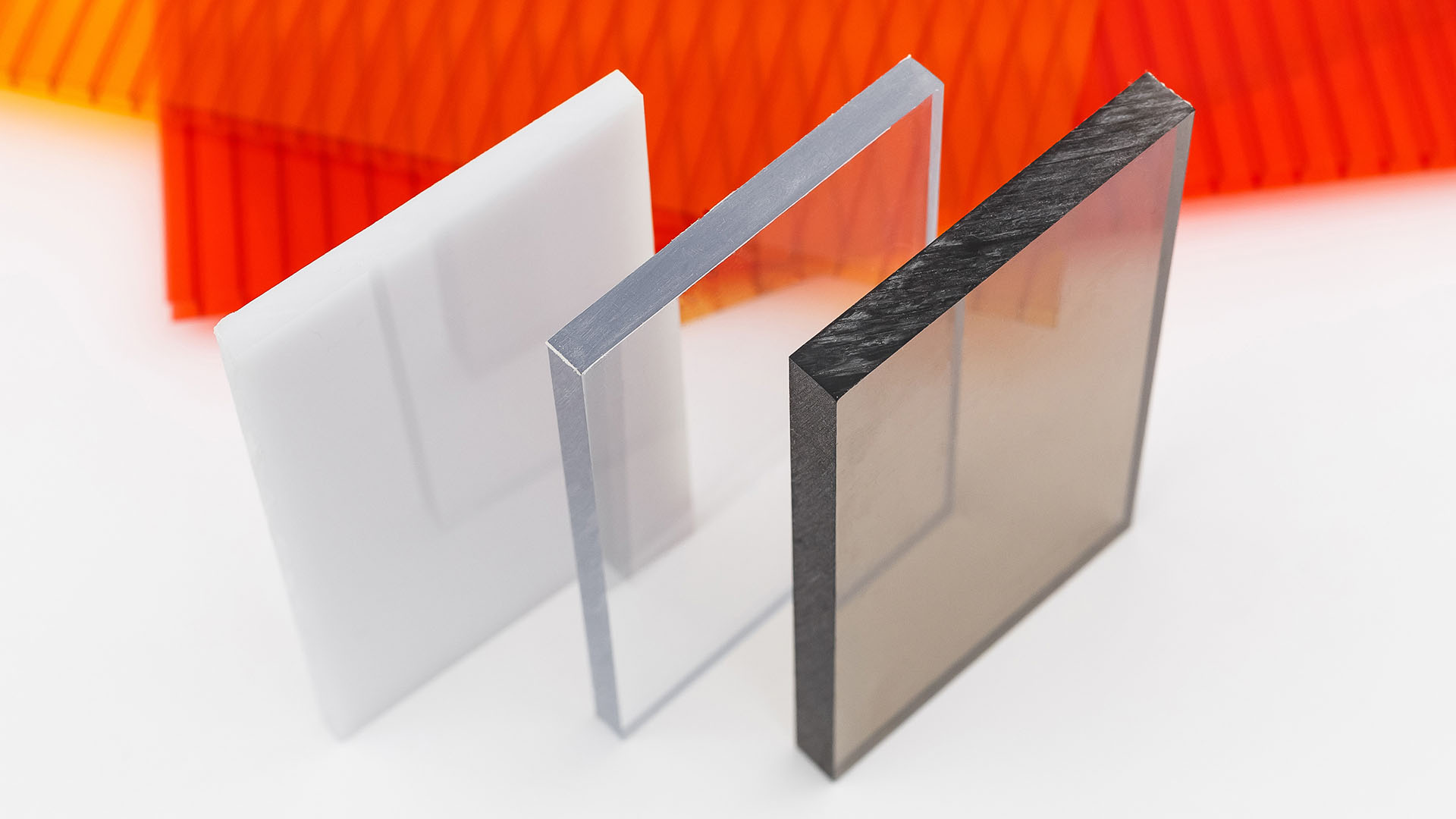

Acrylic has gained a more widespread use because of its ability to replace glass. Acrylic is most often used in sales displays, skylights, lenses, aquariums, and even submarine windows! Also, it’s great because it comes in different thicknesses.

Acrylic Two Way Mirror

- Smart Mirrors

- Observation Rooms

- Home Privacy

- Stage Magic

- Infinity Mirrors

- Hidden Cameras

Advantages of Using Acrylic

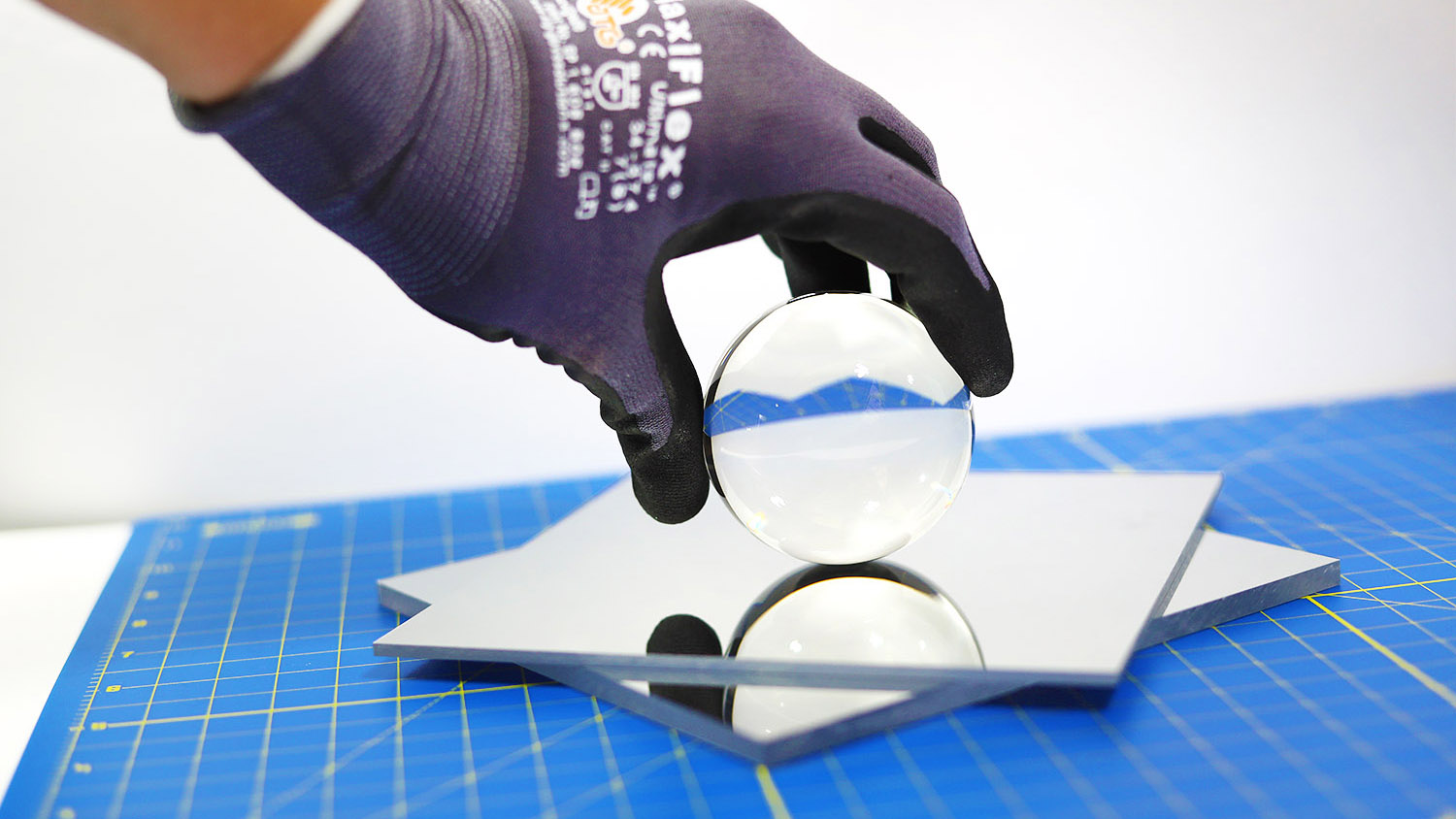

Impact and Pressure Friendly

Acrylic is preferred when safety is concerned because it is impact and pressure friendly. It is 10 times stronger than standard glass. If the acrylic has too much pressure applied it could shatter into small, safe pieces that are easy to pick up.

This is to say acrylic is considered very shatter-resistant but not shatterproof.

Easy to Drill

Acrylic is much easier to drill into when compared to glass. The best drill bit for acrylic is a 1/8″ drill bit. This will reduce chipping around the edge of where you are drilling. High speed drills provide the cleanest result.

Can Be Heated and Shaped

Bending and shaping acrylic is easy, IF you know how. It is all about applying even heat and pressure across the area you want to bend. There are so many things you can create by bending acrylic.

How to Cut Flat Acrylic

To cut acrylic, I recommend using a table saw with a fine tooth saw blade. This kind of blade cuts through the acrylic without chipping the edge of the piece you are working on.

Laser Cutting Acrylic

You can laser cut acrylic to cut out an intricate design or engrave the surface. Depending on the end goal, you’ll want to adjust the settings so it doesn’t damage the acrylic. To cut through acrylic, 10 wats per 0.04″ is ideal. You can reduce the power here for better results but it will take longer to cut through it.

For mirrored acrylic, face the mirror coating side down away from the laser. Otherwise it could hurt the laser cutting machine.

How to Clean Acrylic

To clean acrylic you should not use glass cleaning solutions. For the absolute best results, we recommend the following items:

Novus Cleaning Solution

NOVUS as a brand was established in 1973 as the authority on cleaning acrylic and plexiglass. Utilizing these products will help your acrylic last much longer. This is because standard cleaning products tend to scratch and damage plastic. On the flip side the NOVUS brand has a specific formula that will help save you money long term. No need to replace your acrylic pieces as often. It’s the best kept secret of the century!