Mirror making dates back thousands of years. Throughout history, mirrors have been made using various materials for several purposes. From their origin to now, mirrors have come a long way in quality and concept.

8,000 B.C. – 200 B.C.

Obsidian Stone

The earliest known date of a physical mirror that people could hold in their hands was 8,000 BC, using obsidian stone.

Obsidian is produced by active volcanoes, and was first used in Kenya for pottery and arrowheads. People would heavily polish the stone, which resulted in a beautiful reflection, making it the world’s first mirror!

Over the years, it’s become increasingly associated with black magic, and is known as a scrying mirror or “black mirror”. Not to be confused with the TV show!

The issue with the obsidian mirrors is that they were really heavy, so they usually weren’t made on a large scale. They were mainly used as smaller decorations by the wealthy–unless you were royalty.

Bronze & The Lighthouse of Alexandria

Mirrors made of bronze started to come about around 2000 BC in China, and 2900 BC in Egypt.

These mirrors weren’t anything fancy, just pieces of bronze that were flattened into round disks, then polished. They typically had handles made of wood, metal, or ivory. Much like the obsidian mirrors, these were usually made on the smaller side, unless you were very wealthy.

This can be seen in Egypt with the Lighthouse of Alexandria in 280 BC. There was a large curved mirror at the center that would reflect fire onto a beam. This would help guide those at sea back to safety at night. Money might not buy happiness, but it does buy lighthouses with fancy mirrors!

Archimedes

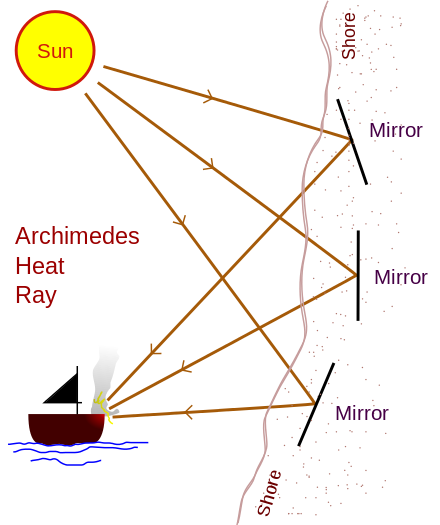

Have you ever heard the story of the famous Mathematician, Archimedes, using mirrors to burn down enemy ships? This was back in 212 BC, when photo evidence clearly wasn’t invented yet, so who can say for sure.

The legend has it that he set up a hexagonal mirror, surrounded by other small mirrors. This was to reflect sun rays on roman ships. The show “Mythbusters” actually recreated this scenario and it worked!

There’s scientific debate over this situation, and the votes are split. What do you think? Did Archimedes use a mirror to take down enemy ships, or was there another method he could have used?

1500’s-1800’s

Mercury Coated Glass Mirrors

Picture this: 15th-16th century Italy.

Well, to be specific, we’re talking about the island of Murano in Venice. This is where the Venetian mirror originated. They were known as Murano glass mirrors.

These mirrors were considered to be the best of their kind, and definitely weren’t cheap. While these mirrors WERE made with glass plates, they were also made with mercury. Rather than using silver or chrome like we do now, mirrors back then had a mercury coating.

Today we know that mercury is a dangerous substance and shouldn’t be used too frequently, as it is toxic. While, I appreciate the forward thinking on their end, I’m super thankful that we have other means of making mirrors now!

Silver Coated Glass Mirrors

If you’re still with me, let’s head to the 1800’s.

This is where we start to see mirrors that are more like the modern day mirror. In 1835, Justus Von Leibig started using silver instead of mercury to coat the glass, thus creating the silvering process that we still use today.

Glass itself is not very reflective, which is why the silvering is needed. Being a fairly sturdy material that is easily polished and smoothed makes it the perfect choice for mirror making! Unless you’re going with an acrylic mirror, but that’s a topic for a different day.

Glass sheets are made from silica, which can be mined or refined from sand. When glass is made from natural crystals of silica, it is known as fused quartz.

However, if it’s a synthetic glass, then it’s going to be synthetic fused silica. The silica or quartz is melted to an extremely high temperature, where it is then poured or rolled into sheets.

Silver is boiled down to a liquid, and then applied in a thin, even coating to the glass. The liquid silver could also be sprayed on spending on what tools are available.

After the silvering process, the mirrors are covered in a protective coating to avoid chips in the reflection, and then polished. If the mirror polishing process isn’t done correctly, there could be waves in the glass which would cause distortion.

Old silver-backed mirrors often have dark lines behind the glass, because the material was coated very thinly and unevenly, causing it to flake off, scratch or tarnish. After 1940, mirror manufacturers used the metal mercury because it spread evenly over the surface of the glass and did not tarnish. Distorted mirrors are okay for fun houses, but not for everyday use!

Present Day

Aluminum Coated Glass Mirrors

Modern mirrors use aluminum rather than silver. The aluminum is applied via vacuum, and will bond directly to cooled glass. Aluminum can oxidize, but a protective layer such as paint can be applied to prevent oxidation. Aluminum actually has the highest level of reflection out of any other metal in the ultraviolet and infrared spectral ranges.

Front surface mirrors, also known as first surface mirrors, are coated in a multi layer automatic coater. This helps to ensure that everything is perfectly even resulting in a flawless reflection. With a standard mirror, the reflection is from the back side, whereas with a first surface mirror the coating is on the face of the glass.

As a result, it has no double image, giving a true reflection. After the aluminum layer is applied, a dielectric layer is added to prevent oxidation & scratching and further enhance the reflection for specific wavelengths. When this is finished, a laminate layer will be applied as protection during the shipping process.

For science & engineering, a superior quality mirror is needed, with a precise reflection. With scientific grade mirrors, there is usually another chemical component added to strengthen the glass. For example, borosilicate glass is composed of silica and boron. This helps it withstand high temperatures!

Reviewing History

Throughout history, from 8,000 BC to present day, mirrors have held an important role in society. Originally used by the rich as a status symbol, to now- where mirrors are a commodity item for the masses, and even used in advanced technology and teleprompters!

The mirror making process has transformed from obsidian glass, to bronze, to toxic mercury, silver, and aluminum. Phew, what a ride!

Thanks for coming on this ride through history with me, mirror connoisseurs !

Thank you for a clear and concise a article as well as video. It was very informative and interesting.

Thank you!

What years was silver used on mirror backings