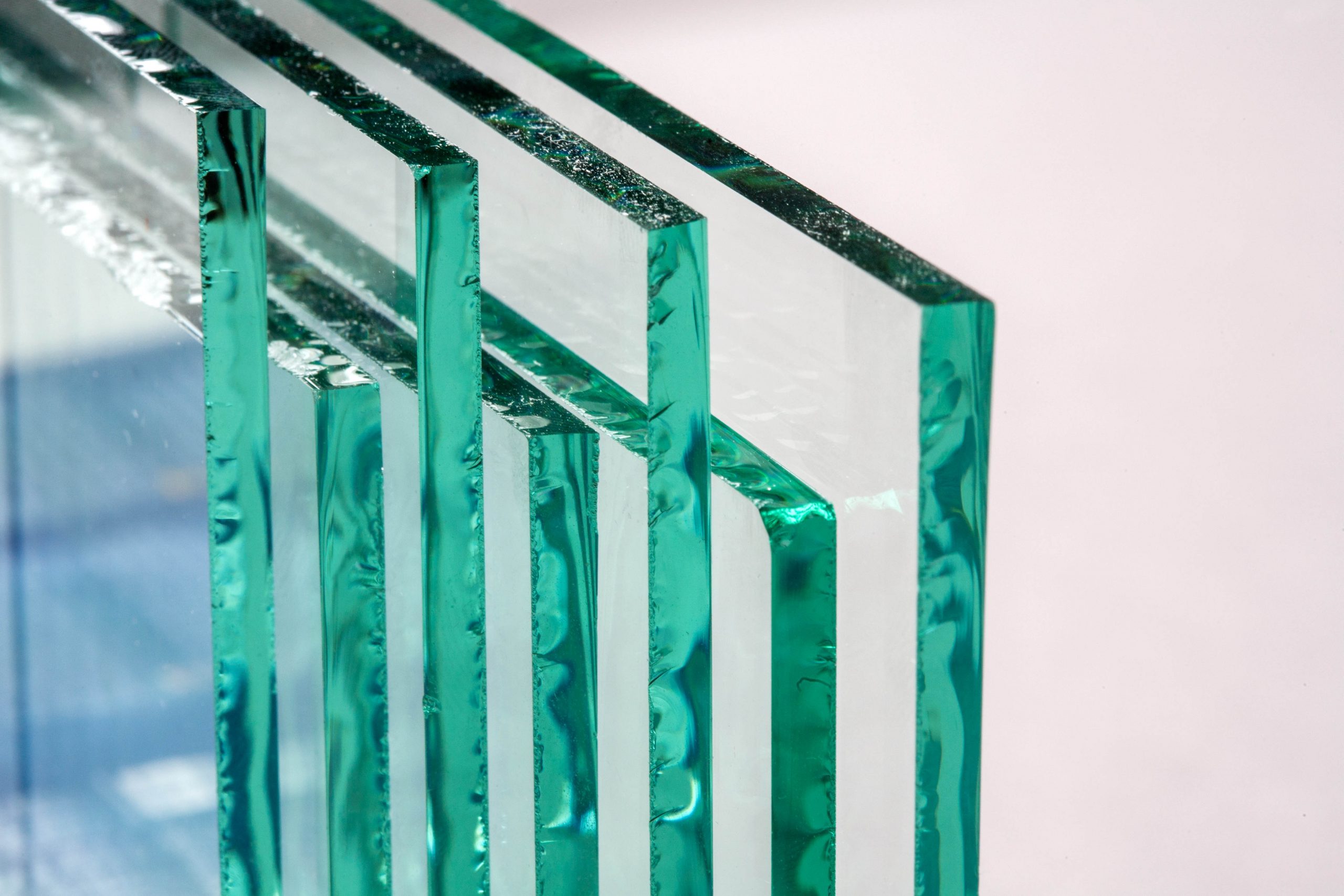

There are many technical and physical properties of glass. The following information will discuss the thermal, optical, chemical, electrical, and mechanical properties of glass. Knowing the different properties of glass will be effective when starting your next project.

The five main properties of glass:

- Thermal

- Optical

- Chemical

- Electrical

- Mechanical

Thermal Properties

Why is it important to know about temperatures of glass? When temperate in glass changes dramatically, the glass can easily break and shatter. Also, temperature is an important factor when creating the glass.

Thermal properties are used to strengthen the glass as well. For example, you can strengthen the glass by heat tempering.

If the temperature is uneven in the glass, it will have an internal pressure at differing levels. This makes the glass prone to fracturing and breaking. This is also known as the thermal shock resistance. This application shows how likely the glass is to break when the temperature changes.

Applications:

What projects would benefit from having glass made from thermal properties? More than you would think.

Projects where there is a higher temperature should take this into consideration. For example, when installing or creating a lighting fixture that uses quartz halogen bulbs, you could use this glass for the glass lens. The bulbs operate at high temperatures, thus emitting a large amount of heat.

Glass manufacturers use this to ensure the client is getting a durable, strong glass. Examples of strong class could be used for: a table, cabinet, window, and more. Thermal properties create critical temperatures that create tempered glass.

The color of glass is also affected by the thermal properties. Colors such as red and yellow are generated from a heating process where the glass is reheated and then cooled.

CTE = Coefficient of Thermal Expansion.

The CTE is used for the Expansion levels in the glass and materials that are installed with it.

It is ESSENTIAL that the materials and glass have matching thermal expansion rates. If the materials and glass don’t match this could cause the glass to fracture.

When you are researching glass, the manufacturer will state the information you need. They will list the maximum temperature and thermal shock resistance.

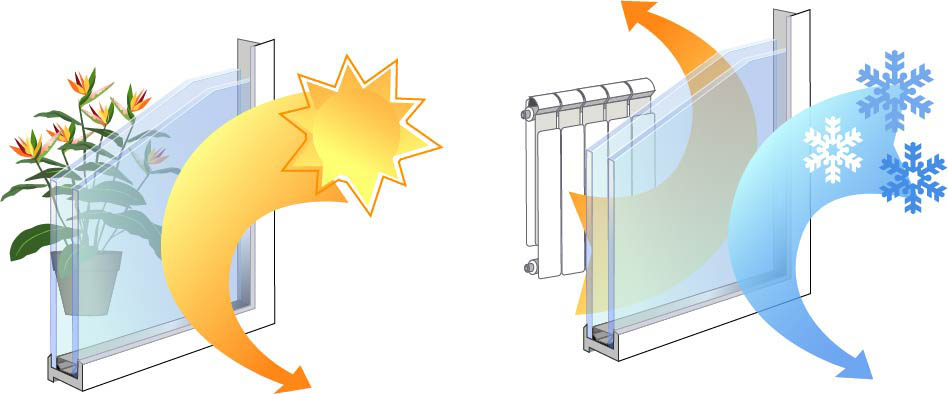

Thermal Shock Resistance

Thermal Shock Resistance: temperature change that glass can handle and remain stable.

An example of the glass that would need a high Thermal shock resistance is glass that would change in temperature. Meaning the glass goes from hot during the day and cold/snow at night.

Optical Properties

To determine how fast the light travels through glass we use the Refractive Index. A Refractive Index means a lower speed of light through the glass.

Light is an electromagnetic wave. When light interacts with the glass engineers are able to decide if the glass being used is correct for that specific application.

According to AZO Optics,

“The refractive index of glass is a very crucial concept because it determines not only how much light is reflected and transmitted, but also its angle of refraction in glass. The refractive index determines the differences between the angle of incidence and the transmission of light with a higher index implying greater differences.”

To determine how the light is converted to heat we would use the Absorption Property.

Absorption is where the color asides in objects or materials. It is based on the physical properties. Such as reflection, light absorption, or emission spectra.

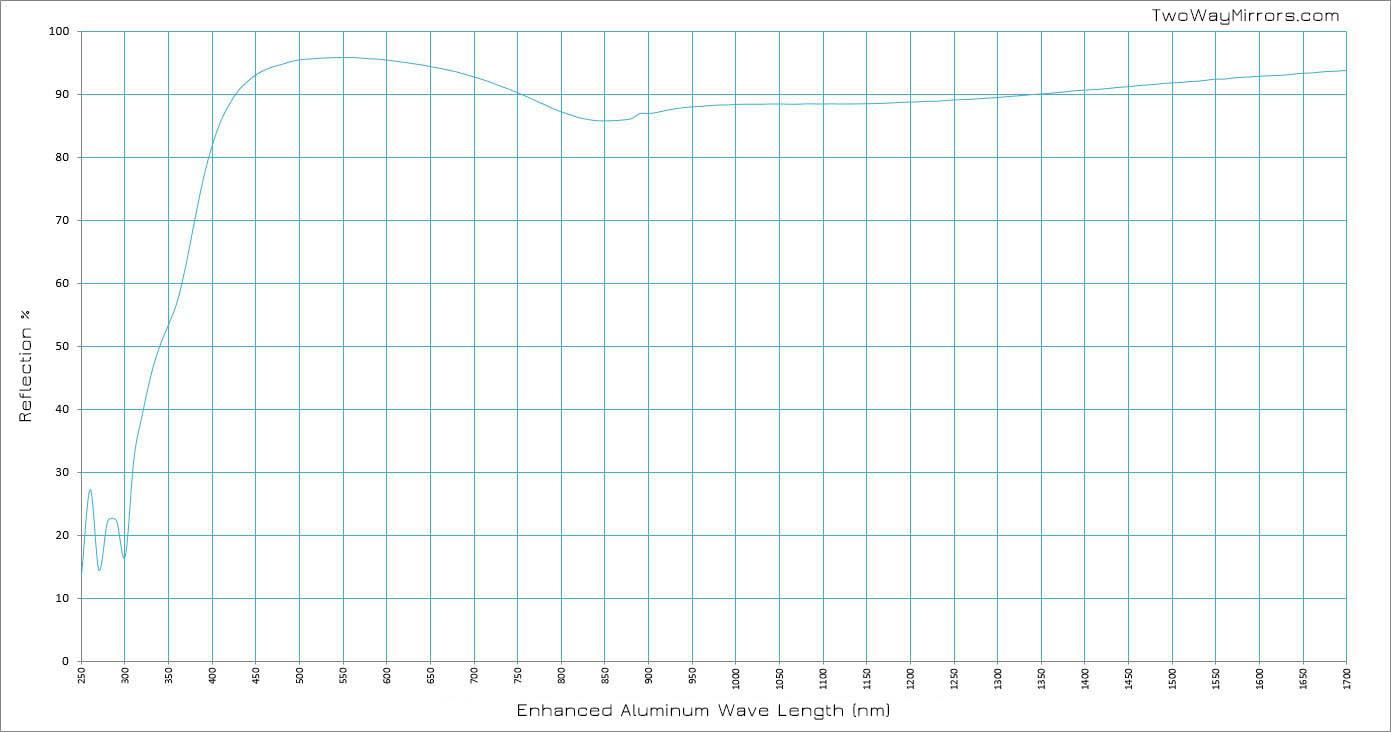

When the mirror coating gets applied to the glass you can also measure the reflection over the different ranges of light.

For Example a First Surface Mirror product has an enhanced aluminum mirror coating and when measuring the percent reflection. The percent reflection is tested from 0 Nanometers – 1,700 Nanometers.

This is a big deal when ordering glass and mirrors for specialized equipment. Enhanced Aluminum has a super high reflection. The Enhanced Aluminum has a reflection of 400 Nanometers – 1,700 Nanometers. But it’s important to know that it’s not great from 250 Nanometers – 350 Nanometers.

Now this range is also known as the UV Spectrum. You’ll need optically flat mirror that has a high reflection in the corresponding range. Then you’d want the UV Enhanced Glass First Surface Mirror Instead.

Chemical Properties

Chemical properties are involved with the glass when it undergoes a chemical reaction or chemical change. This is when the actual material structure is changed.

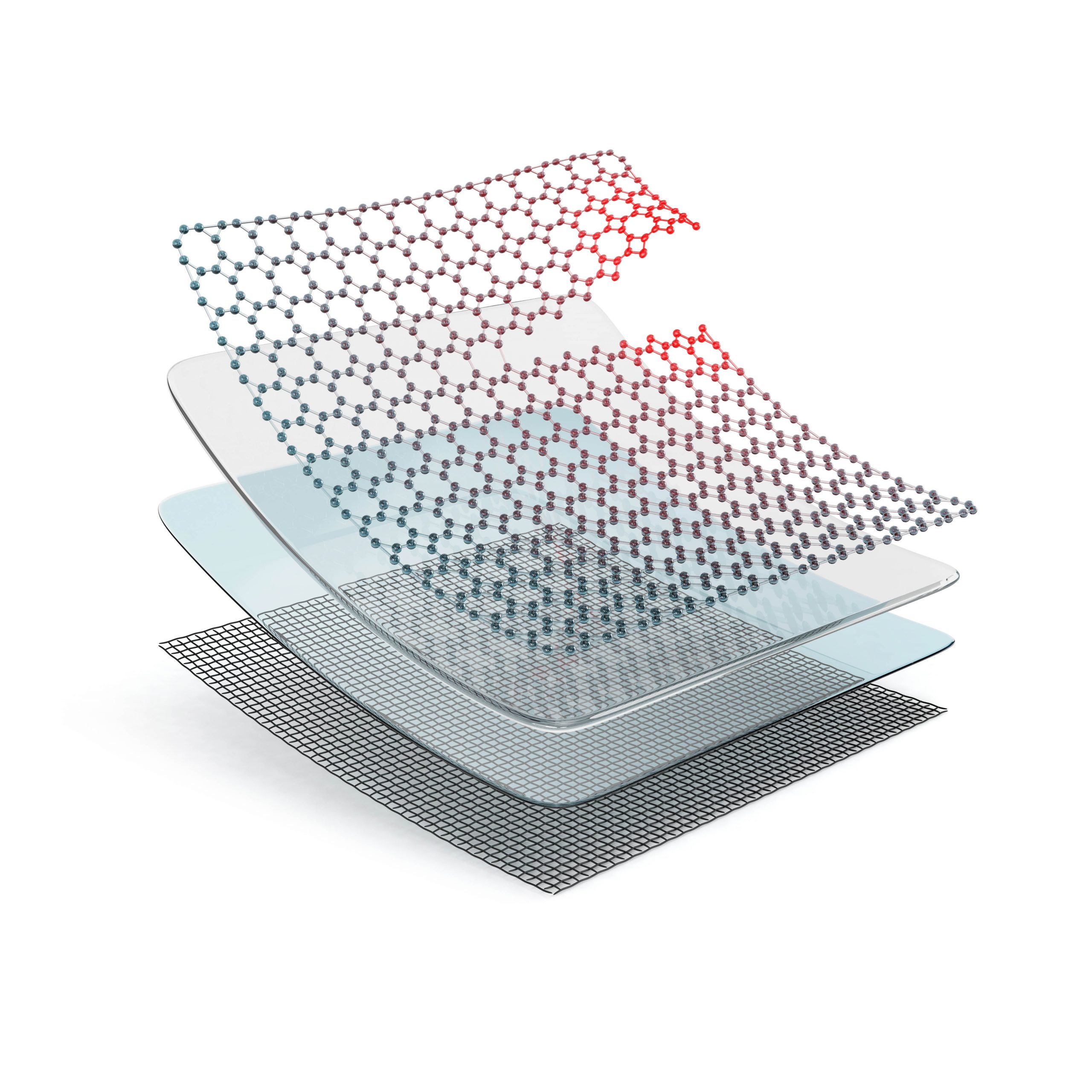

There are thousands of chemical compositions that can be used to make glass. Utilizing the chemical properties can affect the electrical, mechanical, chemical, thermal, and optical properties of the glass.

What are some characteristics of glass?

Most glass contains the following elements: Fluxes, Formers, and stabilizers. According to the Corning Museum of Glass,

“Formers make up the largest percentage of the mixture to be melted. In typical soda-lime-silica glass the former is silica (Silicon dioxide) in the form of sand. Fluxes lower the temperature at which the formers will melt. Soda (Sodium carbonate) and Potash (Potassium carbonate), both alkalis, are common fluxes. Potash glass is slightly more dense than soda glass. Stabilizers make the glass strong and water resistant. Calcium carbonate, often called calcined limestone, is a stabilizer. Without a stabilizer, water and humidity attack and dissolve glass.”

Glass is more resistant to being affected by water, acids, moisture, and alkalis when it’s treated with chemical properties. If it uses silicon dioxide, or other oxides of the Earth, they are more resistant to corrosion.

You might even have some chemically strengthened glass on you right now! Chemically strengthened glass is used in touchscreens for smartphones, tablets, and Gorilla glass applications.

Electrical Properties

Electrical properties in glass are commonly conducted for materials such as lasers, solar energy converters, and semiconductors. Also, electronic devices.

There are a few factors to take into account when dealing with the electrical properties of glass. Different types of glass can have different resistivity. For example, changes in composition. Various factors can have an effect on the glass’s electrical properties like Ac conductivity and DC conductivity. Also, dielectric constant, electrical modulus, and dielectric loss.

When dealing with conductivity the temperature is important. Activation energy is increased when related to the glass composition. Temperature is increased with the resistivity of metals, and decreased with the resistivity of semiconductors.

In different materials, the flow of electricity is different and that’s why there are various variants when creating glass.

To measure the electrical energy glass can stably store you would determine the dielectric constant of the glass.

This is done by gathering the ratio of stored energy in a condenser and glass as the dielectric. Then you’d want to compare it to energy stored with air as the condenser. This is used for Electrical and Electronic devices.

Since clear glass has very little capability to send electric currents through it, it makes a great insulator for electrical equipment.

For Example: We sell the Beamsplitter Mirror. It has a semi-transparent coating on it. Now most people are wondering if the mirror coating has metal in it because there worried about electrical interference.

In most applications the metal in the coating does not cause any problems. This is as long as the equipment can adjust it’s tolerance based on the conductivity of the glass in the end the equipment should work properly.

Mechanical Properties

Mechanical properties are used for hardness, strength, impact resistance, and abrasion. Mechanical properties and chemical properties work hand-in-hand when choosing the correct material for your application.

Impact resistance on glass is used to withstand and hold continuous stress and impact, which is a large force that is placed on the material. When the material is strong, but not hard, the impact could scratch or mark the material but should not break it.

Or, the opposite could happen. If the material is hard, but not strong or tough, it could fracture internally but not hurt the surface of the glass.

Mechanical properties need to be taken into effect for equipment that is around harsh environments. For example: runway light fixtures on an airport runway are constantly having rocks and pebbles flung around them.

Overall, it is important to take all of the properties of glass into consideration when choosing the material for your project.