Follow our video guide as well as these tips and trick for flawless optical glass cutting. You’ll need a few tools and supplies to get started. Practice pieces of glass are a necessity if this is your first glass cutting experience.

It’s easier than you ever imagined! Trust us and let us know if you have any questions along the way. We are here to help.

How to Cut Optical Mirrors!

Full Video Below

What will I need?

Glass Scoring Wheel

Running Pliers

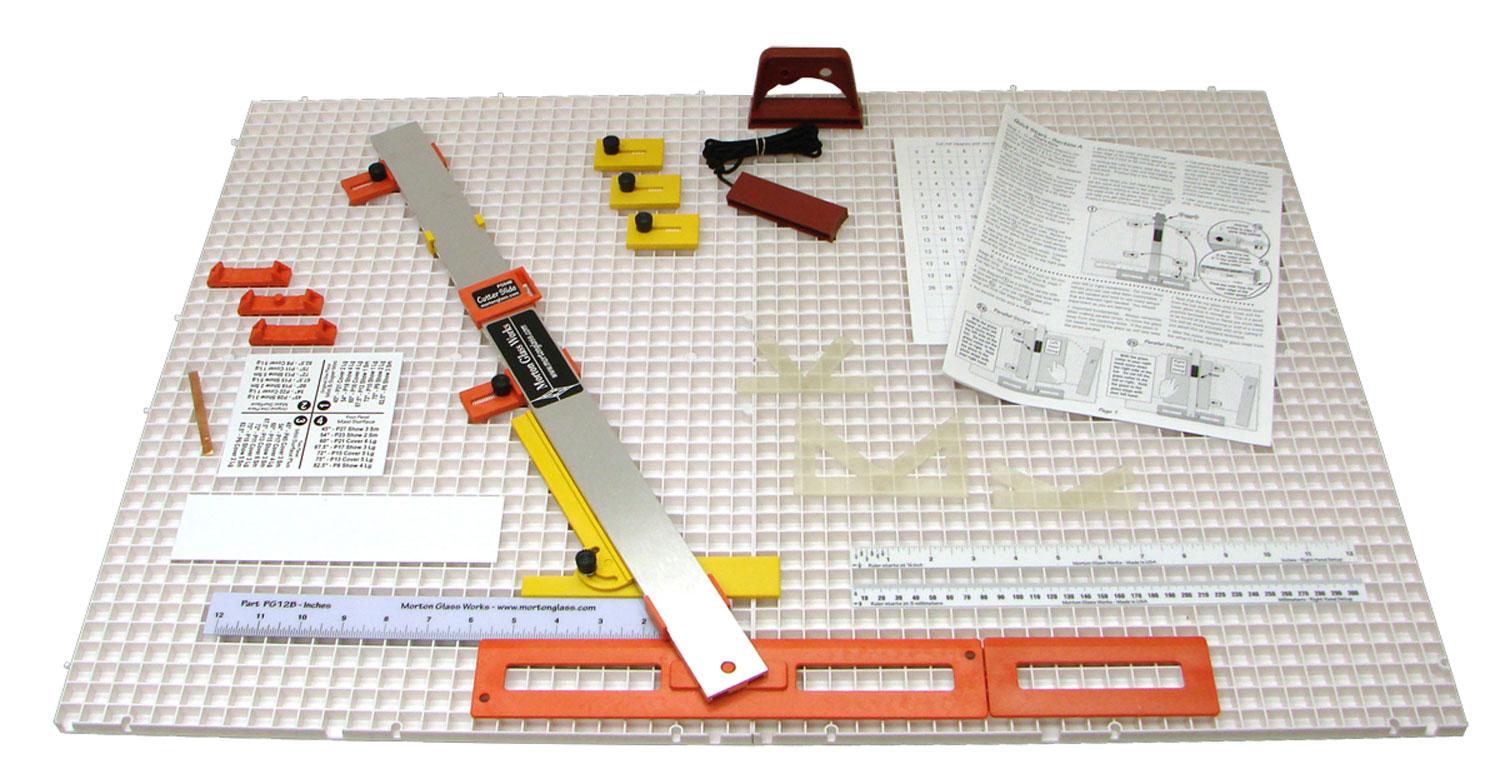

Morton Glass Cutting Table

Safety Gear

What side do I score when cutting a first surface mirror with a laminate protective coating?

Glass first surface mirror will have a blue protective laminate covering the front side of the mirror. You can cut on either side with the glass scoring blade. For 1.1mm thickness first surface mirror it will be easier to cut on the non-laminated side. You will not be able to put enough pressure to cut through the laminate and score the glass at the same time without cracking the glass.

We have samples available for purchase if you need to hone in on your glass cutting skills before custom cutting the mirror for your project.

Where To Start

Begin with your Morton cutting system or flat surface and guides. It is great for cutting 18″ x 24″ mirrors or smaller. We have larger cutting equipment here in our shop, so we use this to precision cut bulk smaller orders around 6″ x 6″ in size.

To start using the Morton Glass Cutting System, set the acrylic grid together. We have it attached to a piece of half-inch plywood to keep it more stable. Place the perpendicular guide lined up with the top and bottom support that snap into place. Take the smaller yellow twists guides and measure the distance from the perpendicular support.

Slide your mirror in place and use the glass score cutting wheel to apply medium even pressure, or until you hear a scoring or scratching sound coming from the glass. You may begin at either the top or the bottom of the mirror. You can only score the glass once so be sure to start at the very edge of the glass and end at the very edge for an even score.

Now that we have our scoreline take the running pliers to the very edge of the glass. Line them up perfectly center with the score. Apply slight pressure until the glass pops apart. Be sure when cutting, scoring and breaking glass to wear eye-protection and glass gloves.

Tips & Tricks

The coating can easily chip if left un-sanded. You can use a sanding block to seam the mirror edges or a wet sander. Always sand the mirror side down. If the mirror coating is sanded into itself chipping my appear.

Shapes

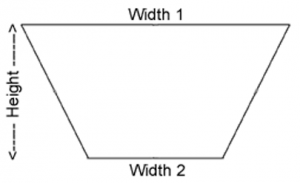

Trapezoids

When cutting glass trapezoids it is all about measuring twice cutting once! Be sure you have the correct width 1, width 2, and height.

Once you have the overall measurements for your trapezoid, line up all four sides and start the scoring and breaking method.

Circles

Depending on the size of your circle, you will either use a smaller circular glass cutter or a more industrial one.

Once the score of the circle is made, trim the excess glass around the mirror. Depending on the thickness of the mirror you may be able to break the glass safely from the back by tapping under the scoreline with running pliers. You can usually do this with thinner material.

With 1/4″ glass you will need to score and break as close to the original score line as possible. Use this method here with tons of practice to perfect breaking around your circle perfectly.

Thanks for sharing this ideas. I had so much fun reading this full of information posts!

There are different tools comes in the market by the help of that you can easily cut the mirror in any shape as from my view cropping mirror for installation is not that difficult if your proper equipment and professional help to do so.